Retirement and forum shutdown (17 Jan 2022)

Hi,

John Howell who has managed the forum for years is getting on and wishes to retire from the role of managing it.

Over the years, he has managed the forum through good days and bad days and he has always been fair.

He has managed to bring his passion for fish keeping to the forum and keep it going for so long.

I wish to thank John for his hard work in keeping the forum going.

With John wishing to "retire" from the role of managing the forum and the forum receiving very little traffic, I think we must agree that forum has come to a natural conclusion and it's time to put it to rest.

I am proposing that the forum be made read-only from March 2022 onwards and that no new users or content be created. The website is still registered for several more years, so the content will still be accessible but no new topics or replies will be allowed.

If there is interest from the ITFS or other fish keeping clubs, we may redirect traffic to them or to a Facebook group but will not actively manage it.

I'd like to thank everyone over the years who helped with forum, posted a reply, started a new topic, ask a question and helped a newbie in fish keeping. And thank you to the sponsors who helped us along the away. Hopefully it made the hobby stronger.

I'd especially like to thank John Howell and Valerie Rousseau for all of their contributions, without them the forum would have never been has successful.

Thank you

Darragh Sherwin

Building Tanks from Reclaimed glass

- Johnmorrin (John Morrin)

- Offline

- Junior Member

-

- Posts: 57

- Thank you received: 0

Heres what I got this evening :

Heres a cutting bench I set up , Its actually an old hospital bed and has hydraulic height adjustment

One tank cut , edges sanded and ready to be cleaned and siliconed :

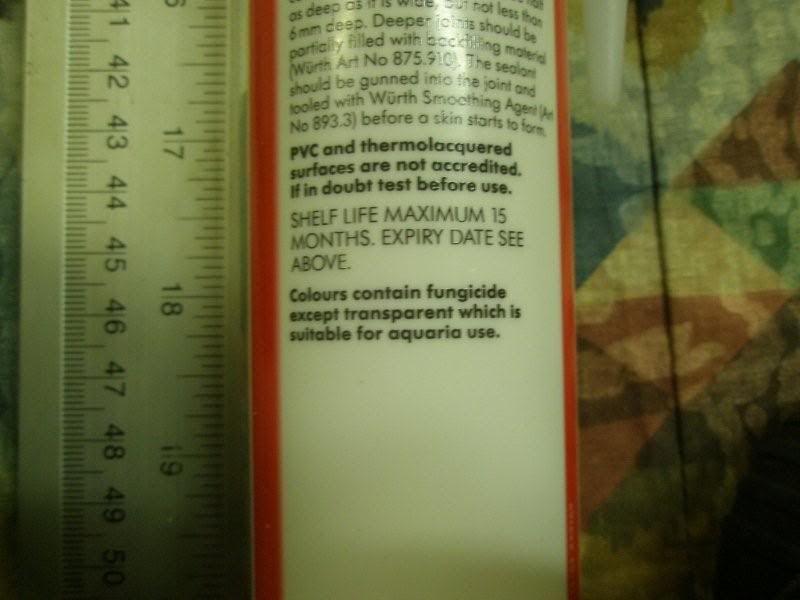

A box of clear silicone I got at trade price in work from our Wurth supplier, 5 euro a tube

And just to be sure its safe

Thats about it for now , ill finish up this tank tomorrow evening , and cut pieces for a few more.Its 24" x 12" x 12" if your wondering

Stay tuned for updates

Please Log in to join the conversation.

- platty252 (Darren Dalton)

-

- Offline

- Moderator

-

- Posts: 2309

- Thank you received: 127

That's some work shop you have. You seem to have everything. I think you should change your user name to steptoe:laugh:

Please Log in to join the conversation.

- LimerickBandit (Donal Doran)

- Offline

- Premium Member

-

- Posts: 696

- Thank you received: 0

LB

Please Log in to join the conversation.

- Johnmorrin (John Morrin)

- Offline

- Junior Member

-

- Posts: 57

- Thank you received: 0

Should get this on siliconed up this evening and glass cut for two or three more all going well

Please Log in to join the conversation.

- Johnmorrin (John Morrin)

- Offline

- Junior Member

-

- Posts: 57

- Thank you received: 0

Then I had to strip down one of the double glazed units to get some more glass for the second tank.This is not for the faint of heart as the pressure you have to put on the stanley knife to cut through the black sealer is incredible.

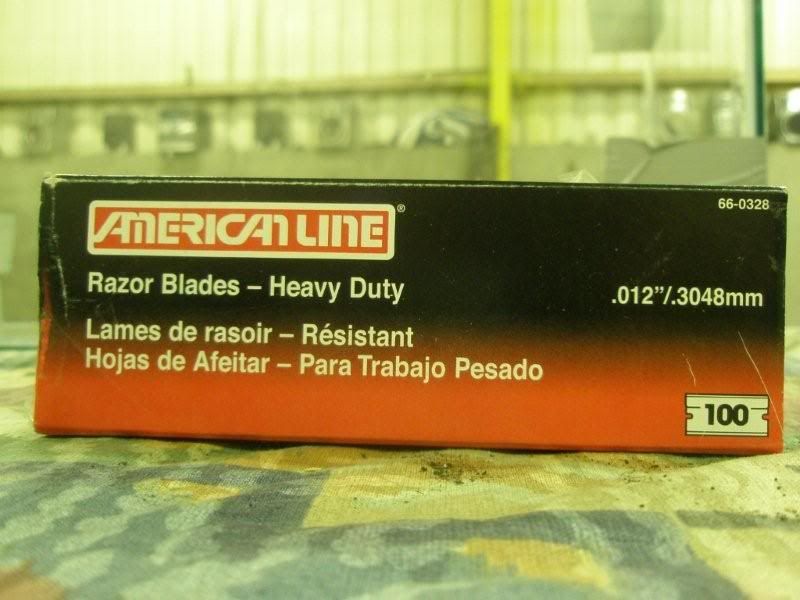

After Splitting , all the black sealer has to be scraped off the glass.Luckily I remembered to get some blades from work

I then made them into a scraper with the trusty vice-grips

After cleaning the glass and sanding the edges it was ready for assembly.I Didnt get many pics of this cos it has to be done quickly before the silicone starts going off.

One of the seams

The two tanks side by side , have to leave the cure now for 24hrs until I can test with water.

Oh and the 110,000BTU heater helped with the cold in the shed this evening

Thats all for this evening folks , As always stay tuned for updates

Please Log in to join the conversation.

- gerryberry (Jeff Daly)

-

- Offline

- Senior Member

-

- Posts: 480

- Thank you received: 4

Great thread keep it up:cheer:

GB

Please Log in to join the conversation.

- Posts: 1420

- Thank you received: 2

Great to read this and see the stages have to say you got more shots than i would.

I have one question what did you use to sand the edges. a silly question. in the past i was told a rub of an oil stone for this job.

Mickey

Mickey Wallace & Cath Woods

Please Log in to join the conversation.

- Johnmorrin (John Morrin)

- Offline

- Junior Member

-

- Posts: 57

- Thank you received: 0

Im also toying with the idea of making a 6ft x 12" x 12" for a cichlid display tank , dunno yet tho cos long cuts in glass are tricky

Please Log in to join the conversation.

- Johnmorrin (John Morrin)

- Offline

- Junior Member

-

- Posts: 57

- Thank you received: 0

Please Log in to join the conversation.

- sheag35 (Seamus Gillespie)

-

- Offline

- Platinum Member

-

- 086 8442267

- Posts: 2740

- Thank you received: 274

Fishkeeping the Only way to get wet and wild

currently 25 tanks, and breeding is the aim of everything i keep

location:Limerick

Please Log in to join the conversation.

- duzzy1 (Martin Kennedy)

-

- Offline

- Elite Member

-

- Posts: 824

- Thank you received: 22

Please Log in to join the conversation.

- LimerickBandit (Donal Doran)

- Offline

- Premium Member

-

- Posts: 696

- Thank you received: 0

Please Log in to join the conversation.